VSI vertical shaft impact sand making machine fault quick solution method

2017-10-11 839

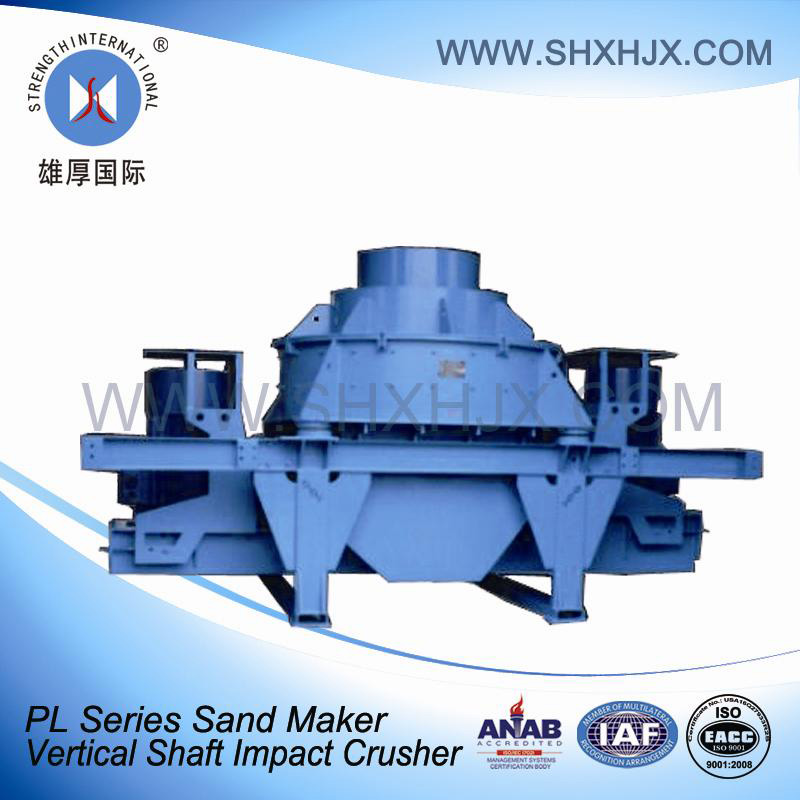

PL series vertical shaft impact crusher (VSI sand making machine) vertical shaft impact crusher is 50% energy saving than the traditional sand making machine, it can make all kinds of rocks, sand, river pebbles into construction sand with various particle sizes, is currently widely used machine sand equipment. Because of the large strength of its crushed materials, there will be some problems in the daily work of the sand making machine, and what we can do is to reduce and avoid the occurrence of faults as much as possible. In order to work more efficiently, the staff needs to understand the frequent failures of the sand making machine and how to solve them quickly. Today, I will introduce you to the causes and treatment methods of several common faults, and if you encounter such problems, you can solve them in time.

1、In the production process of the sand making machine, there is a certain body swing, but the amplitude is not large, if the body swing is particularly violent, then there may be three reasons

The cause of the failure:

1)The wear parts on the impeller are relatively worn;

2)The feed pellets are too large;

3)The impeller runner has a blockage, which makes the feed uneven and swing.

Workaround:

1)Replace the wearing parts to balance the impeller inside the sand making machine;

2)Strictly control the feed particle size, sand making machine in the design, the maximum feed particle size of the equipment is generally 4 to 5 cm, generally speaking, the equipment feed particle size in 3 to 4 cm when the amount of finished sand can reach the most, if the feeding too large will cause the equipment swing too large, if the feed is too small, the collision crushing is not sufficient and it is difficult to achieve the amount of finished sand that meets the full standard;

3)Remove the blockage from the impeller runner and clean the crushing chamber frequently。

2、The device emits an abnormal noise during operation

The cause of the failure:The connecting bolts inside the sand making machine or the wearing parts such as liners and impellers are loose and fall off。

Workaround:Stop immediately and re-fasten and re-install loose or detached parts。

3、Bearings are inflexible in operation

The cause of the failure:The bearing seal cover of the sand making machine is caused by foreign matter such as material entering the seal。

Workaround:Open the sealing cap and remove foreign objects。

4、The bearing temperature rises

The cause of the failure:

1)Dust and foreign matter enter the bearing parts;

2)The bearing is damaged by the grind;

3)Bearings lack oil.

Workaround:

1)Clean up foreign objects;

2)Replace with new bearings;

3)Increase lubricating oil on time.

5、The upper and lower sealing rings on the shaft are damaged

The cause of the failure:The upper (lower) bushing causes heat due to the upper (lower) movement and friction of the bottom surface of the upper (lower) gland, which causes damage over time。

Workaround:Replace with new upper and lower end seals.

6、Oil leakage from the upper and lower ends of the shaft

The cause of the failure:Because the sealing ring moves up and down with the bearing, the sealing ring is worn and oil leakage occurs.

Workaround:Replace the seal.

7、The discharge particle size becomes larger

The cause of the failure:

1)The long-term operation of the equipment causes the V-belt of the transmission part to loosen;

2)The feed grain is too large;

3)The impeller speed is unreasonable and the efficiency becomes low.

Workaround:

1)Adjust the V-belt tightness;

2)Feeding in strict accordance with the feeding requirements of the sand making machine (if the feeding is too large, the equipment swing is too large, if the feeding is too small, the collision crushing is not sufficient and it is difficult to achieve the qualified finished sand volume);

3)Adjust the impeller speed until it reaches the ideal standard.

8、The machine suddenly became louder and rumbling

The cause of the failure:

1)There is a problem with the bearing or gear;

2)The bolts are loose;

3)The wearing parts are severely worn.

Workaround:

1)Check whether the bearings and gears are intact, and repair or replace them in time;

2)Tighten the bolts;

3)Replace wearing parts.

9、Excessive idling resistance

The cause of the failure:There is a material blockage in the sealing cover on the bearing.

Workaround:Open the upper sealing cover to remove the blocked material from the bearing and clean the bearing, while checking whether the corresponding device is blocked by the material.

10、There is a sound of metal colliding in the sand making machine

The cause of the failure:Liners, impellers are loose or other components are worn off.

Workaround:The entire machine is inspected, fastened or replaced with related parts.

The sand making machine plays an irreplaceable role in the sand making of various ores, and is currently the most effective, practical and reliable sand making equipment. The above 10 types of faults are common problems encountered in the production of sand making machines, in addition, if there are other unexplained faults in operation, they should not be taken lightly, and should be stopped immediately to avoid damage to other components.

Previous:Crushing and screening equipment mass batch parts delivery site

More related content:

Crushing and screening equipment mass batch parts delivery site (2017-12-09)

A certain bureau of China Railway ordered crushing and screening into sets of equipment delivery site (2017-09-29)